- Home

- Wood Stove Guide

- Modern Wood Stoves

Modern Wood Stoves

This post may contain affiliate links so I earn a commission.

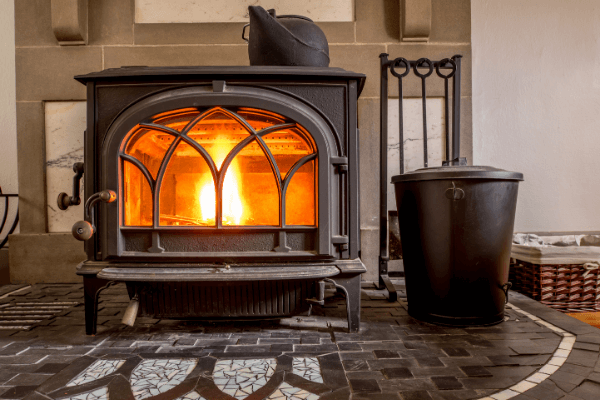

When thinking about modern wood stoves we must first consider the traditional wood burning stove, a simple idea that has stood the test of time.

A metal box, vented outside that you can safely put a fire in to warm yourself and your home.

For years this is all that a wood stove was, with little consideration for how fire functioned or ways it could be improved upon.

Like most things over time, the ideas seemed to get stale and people wondered if there was a better way to heat our homes than these smoldering, belching metal boxes.

As more consideration was given to clean air, these previously unnoticed boxes came into the sights of regulators who saw an opportunity to encourage change.

From this increased scrutiny and new regulations modern wood stoves were developed.

While many are classical in style, the increased focus on design has also lead to contemporary designs to complement modern architectural developments and trends.

Antique Wood Burning Stoves

Old style wood stoves were generally simple, a basic box with a pipe out and an air inlet control, to provide further control over the burn there were often dampers placed in the chimney pipe that when turned could further restrict gas flow.

Many of these stoves also had firebrick to protect the metal in the stove from degeneration from contact with fire and super heated gasses which could be corrosive.

These stoves burned at a low temperature often smoldering and when pushed to burn hotter they would send flames licking up the chimney, a sure way to lose heat and increase the danger of a chimney fire in masonry chimneys which could in extreme cases cause house fires.

Old Franklin Wood Burning Stove

Old Franklin Wood Burning StoveThe firebrick lined stoves further exacerbated things by insulating the stove from absorbing heat and encouraging flammable gasses to escape into the chimney where they could not provide any useful service.

When buying my farm years ago, I found that both of the chimneys had been damaged by chimney fires previously, resulting in one having to be completely dismantled and the other stripped of its tiles and relined in stainless steel.

This was the result of old style wood stoves being fired hot.

Here where we are at best zone 4b, we do tend to run our stoves hot to provide the needed heat.

With old style wood stoves most of that heat is being thrown up the chimney potentially causing property damage.

Because of this it is surprising that it took so long for a change to occur, but then I guess old habits do die hard.

Modern Wood Stoves - Catalytic

There were two significantly different methods used to try to increase efficiency in the new generation of wood stoves.

Not surprisingly some engineers chose to look at this problem of particulate emissions and find a comparable situation.

Vehicle emissions had already been under scrutiny for years and there was a tried and true method of reducing tailpipe emissions that was required on all newer vehicles.

Using a catalyst to encourage cleaner burning like the catalytic convertor in vehicle tailpipes seemed like a viable option.

Vermont Castings was one of the early leaders in the development of catalytic wood stoves.

Their technology did show a shocking reduction in particulate emissions with a major caveat, the particulate emissions would go up steadily for the first few seasons, by the 5th season the stove was actually just as bad or worse than a stove with no reburn technology.

Vermont Castings Wood Stove

Vermont Castings Wood StoveThis did not prove to be as popular as Vermont Castings had hoped, the market by and large was made up of traditional wood stove users, who did not like the idea of having to incur the cost or effort of replacing a catalyst block in the exhaust of the stove every few seasons.

In this case old habits did die hard and this was part of the difficulty Vermont Castings came into with their business, and the reason there is not a good resale market for those stoves.

Vermont Castings had made a calculated gamble though and thought this was the best option while still allowing stoves to be top loading, which was historically popular.

Modern Wood Stoves - Secondary Burn

The other major technology of modern wood stoves, is the reburn chamber.

With this technology top loading stoves were no longer considered a viable option.

The reburn chamber is a simple concept that was probably counter intuitive because of its simplicity.

This technology is based on the understanding that wood can undergo primary and secondary combustion.

The first phase of wood combustion is at a relatively low temperature, this is the type of heat given off by smoldering wood.

What old wood stoves were missing out on was that primary combustion releases a large quantity of flammable gasses that were being allowed to go up the chimney where they would pass out into the atmosphere as pollution if they did not first burn in the chimney.

This was giving up a huge amount of potential energy as pollution instead of heat.

So creating a system where the flammable gasses are completely burned would do two things.

It would drastically reduce, almost eliminating particulate emission, resulting in the emissions being mostly invisible except on the coldest days, and it would greatly increase the amount of heat that a wood stove would put out.

This simple method could be achieved by putting a horizontal baffle over the firebox that would allow gasses to enter at one end and the exhaust to go out the other end up the chimney.

This space separated by a metal plate on top of the firebox, covered in a fire blanket to control temperature exchange between the lower firebox and upper reburn chamber, allowed the flammable gasses which the primary combustion released to burn, incinerating most of the exhaust particulates as well.

What has proven to be the most important part from a user and a marketing standpoint is that this occurs without the use of any additional technologies and the reburn chambers effectiveness does not diminish over time.

It is free with the design of the stove.

It increases efficiency by increasing burn temperatures.

This requires a controlled metering of air.

By making the modern wood stove more air tight to its environment and further controlling the volume of fresh air intake, how the wood burned could be strictly controlled.

When these modern wood stoves come up to temperature they give off impressive amounts of heat, and on the ceramic glass front models this can also be seen as quite a show, with secondary combustion creating a visual firestorm.

Modern Wood Stoves - Overall

If there is one main drawback to modern wood stoves, it is that it requires your firewood to be more carefully prepared.

They want their wood to be well seasoned and dry.

Often times these stove prefer the wood to be split into smaller pieces and even for smaller rounds to be broken.

Once they are up to temperature they are not so finicky, but trying to get one started without good dry kindling and dry wood can sometimes be a little bit of a chore.

Considering how well they produce heat I think a little difficulty can be dealt with sometimes.

Wood stove technology keeps improving, getting more heat out of less wood.

What does not change is as steward of this process we must do our best to provide the traditional requirement of dry seasoned wood and kindling.

As the technology continues to improve we will just be asked to provide less of it.

About the Author

Obsessed with firewood, Nick is behind over 350+ of Firewood For Life's articles, as well as countless reviews, guides and YouTube videos to help readers like you reduce heating costs and create the perfect fire.